Stationary phases

HPLC Phases

ASTRA - CHROMSERVIS

| Packing Material | Particle Size (µm) | Pore Size (Å) | Surface Area (m2/g) | Carbon Load (%) | pH Range |

|---|---|---|---|---|---|

| C18-HE | 2, 3, 5, 10 | 100 | 330 | 17 | 2-9 |

| C18-AQ | 2. 3, 5 | 100 | 330 | 13 | 2-9 |

| C18-BDS | 3, 5 | 140 | 170 | 11 | 2-8 |

| C8-HE | 5 | 100 | 330 | 11 | 2-9 |

| C8-BDS | 3, 5 | 140 | 170 | 6 | 2-8 |

| Phenyl-Hexyl-HE | 3, 5 | 100 | 330 | 11 | 2-7.5 |

| DM | 3, 5 | 100 | 205 | 12 | 2-9 |

| Diol | 3, 5 | 100 | 330 | 5 | 2-7.5 |

ARION - CHROMSERVIS

| Packing Material | Particle Size (µm) | Pore Size (Å) | Surface Area (m2/g) | Carbon Load (%) | pH Range |

|---|---|---|---|---|---|

| Plus C18 | 1.7, 2.2, 3, 5, 10, 15 | 100 | 420 | 18 | 1.5-10 |

| Polar C18 | 2.2, 3, 5, 10, 15 | 120 | 325 | 16 | 1.5-7.0 |

| C8 | 3, 5 | 120 | 325 | 11 | 2.0-7.0 |

| Phenyl-butyl | 2.2, 3, 5 | 100 | 300 | 12 | 1.5-7.5 |

| NH2 | 2.2, 3, 5 | 120 | 325 | 5 | 2.0-6.5 |

| CN | 3, 5, 10 | 120 | 325 | 8 | 2.0-7.0 |

| HILIC Plus | 2.2, 3, 5 | 120 | 420 | - | 1.5-7.0 |

| Si | 2.2, 3, 5, 10 | 100 | 420 | - | 1.5-7.0 |

| SAX | 5 | 120 | 325 | - | 1.0-7.5 |

| SCX | 5 | 120 | 325 | - | 1.0-7.5 |

More information is available in Column care guide aswell.

CHROMSHELL - CHROMSERVIS

| Packing Material | Particle Size (µm) | Pore Size (Å) | Surface Area (m2/g) | Carbon Load (%) | pH Range |

|---|---|---|---|---|---|

| CHROMSHELL® C18 Plus | 2.6 | 85 | 130 | 9 | 1.5-7.5 |

| CHROMSHELL® C18-XB | 2.6 | 85 | 130 | 8 | 1.5-8.0 |

| CHROMSHELL® C18 Polar | 2.6 | 85 | 130 | 6.5 | 1.5-7.0 |

KINETEX - PHENOMENEX

| Packing Material | Particle Size (µm) | Pore Size (Å) | Effective Surface Area (m2/g) | Carbon Load (%) | pH Range |

|---|---|---|---|---|---|

| Kinetex XB-C18 | 5, 2.6 | 100 | 200 | 10 | 1.5-8.5* |

| Kinetex C18 | 5, 2.6 | 100 | 200 | 12 | 1.5-8.5* |

| Kinetex C8 | 2.6 | 100 | 200 | 8 | 1.5-8.5* |

| Kinetex PFP | 5, 2.6 | 100 | 200 | 9 | 1.5-8.5* |

| Kinetex HILIC | 2.6 | 100 | 200 | 0 | 2.0-7.5 |

| Kinetex Phenyl-Hexyl | 5, 2.6 | 100 | 200 | 11 | 1.5-8.5* |

* Columns are pH stable from 1.5 to 10 under isocratic conditions. Columns are pH stable from 1.5 to 8.5 under gradient conditions.

Kinetex 2.6µm columns with ID 2.1mm are pressure stable up to 1000 bar, otherwise up to 600 bar.

Kinetec chore-shell colums can be replace by new ChromShell colums. Just try it.

LUNA - PHENOMENEX

| Packing Material | Particle Size (µm) | Pore Size (Å) | Surface Area (m2/g) | Carbon Load (%) | pH Range | USP Packing |

|---|---|---|---|---|---|---|

| Luna Phenyl-Hexyl | 3,5,10,15 | 100 | 400 | 17.5 | 1.5-10.0 | L11 |

| Luna Silica (2) | 3,5,10,15 | 100 | 400 | - | - | L3 |

| Luna C5 | 5,10 | 100 | 440 | 12.5 | 1.5-10.0 | - |

| Luna C8 | 5,10 | 100 | 440 | 14.75 | 1.5-10.0 | L7 |

| Luna C8 (2) | 3,5,10,15 | 100 | 400 | 13.5 | 1.5-10.0 | L7 |

| Luna C18 | 5,10 | 100 | 440 | 19 | 1.5-10.0 | L1 |

| Luna C18 (2) | 2.5,3,5,10,15 | 100 | 400 | 17.5 | 1.5-10.0 | L1 |

| Luna CN | 3,5,10 | 100 | 400 | 7.0 | 1.5-10.0 | L10 |

| Luna NH2 | 3,5,10 | 100 | 400 | 9.5 | 1.5-11.0 | L8 |

| Luna SCX | 5,10 | 100 | 400 | 0.55% Sulfur Load | 2.0-7.0 | L9 |

| Luna HILIC | 3,5 | 200 | 200 | - | 1.5-8.0 | - |

| Luna PFP(2) | 3 5 | 100 | 400 | 5.7 | 1.5-8.0 | L43 |

GEMINI - PHENOMENEX

| Packing Material | Particle Size (µm) | Pore Size (Å) | Surface Area (m2/g) | Carbon Load (%) | pH Range | USP Packing |

|---|---|---|---|---|---|---|

| Gemini C18 | 3,5,10 | 110 | 375 | 14 | 1.0-12.0 | L1 |

| Gemini C6-Phenyl | 3,5 | 110 | 375 | 12 | 1.0-12.0 | L11 |

| Gemini NX | 3,5,10 | 110 | 375 | 14 | 1.0-12.0 | L1 |

SYNERGI - PHENOMENEX

| Packing Material | Particle Size (µm) | Pore Size (Å) | Surface Area (m2/g) | Carbon Load (%) | pH Range | USP Packing |

|---|---|---|---|---|---|---|

| Synergi Max-RP | 2.5 | 100 | 400 | 17 | 1.5-10.0 | - |

| Synergi Hydro-RP | 2.5 | 100 | 400 | 19 | 1.5-7.5 | L1 |

| Synergi Polar-RP | 2.5 | 100 | 440 | 11 | 1.5-7.0 | L11 |

| Synergi Fusion-RP | 2.5 | 100 | 440 | 12 | 1.5-10.0 | L1 |

| Synergi Max-RP | 4,10 | 80 | 475 | 17 | 1.5-10.0 | - |

| Synergi Hydro-RP | 4,10 | 80 | 475 | 19 | 1.5-7.5 | L1 |

| Synergi Polar-RP | 4,10 | 80 | 475 | 11 | 1.5-7.0 | L11 |

| Synergi Fusion-RP | 4,10 | 80 | 475 | 12 | 1.5-10.0 | L1 |

ONYX - PHENOMENEX

| Packing Material | Macropore Size (µm) | Pore Size (Å) | Surface Area (m2/g) | Carbon Load (%) | pH Range | USP Packing |

|---|---|---|---|---|---|---|

| Onyx Silica | 2 | 130 | 300 | 0 | 2.0-7.5 | - |

| Onyx C8 | 2 | 130 | 300 | 11 | 2.0-7.5 | - |

| Onyx C18 | 2 | 130 | 300 | 18 | 2.0-7.5 | - |

JUPITER - PHENOMENEX

| Packing Material | Particle Size (µm) | Pore Size (Å) | Surface Area (m2/g) | Carbon Load (%) | pH Range | USP Packing |

|---|---|---|---|---|---|---|

| Jupiter C4 | 5,10,15 | 300 | 170 | 5.0 | 1.5-10.0 | L26 |

| Jupiter C5 | 5,10,15 | 300 | 170 | 5.5 | 1.5-10.0 | - |

| Jupiter C18 | 5,10,15 | 300 | 170 | 13.3 | 1.5-10.0 | L1 |

| Jupiter Proteo C12 | 4,10 | 90 | 475 | 15.0 | 1.5-10.0 | - |

GraceSmart - GRACE

| Packing Material | Particle Size (µm) | Pore Size (Å) | Surface Area (m2/g) | Carbon Load (%) | pH Range | USP Packing |

|---|---|---|---|---|---|---|

| GraceSmart C18 | 3,5 | 120 | 220 | 10 | 2.0-9.0 | L1 |

Alltech® Prevail - GRACE

| Packing Material | Particle Size (µm) | Pore Size (Å) | Surface Area (m2/g) | Carbon Load (%) | pH Range | USP Packing |

|---|---|---|---|---|---|---|

| Prevail C18 | 3,5 | 110 | 350 | 17 | L1 | |

| Prevail C18 Select | 3,5 | 110 | 350 | 15 | L1 | |

| Prevail C8 | 3,5 | 110 | 350 | 8 | L7 | |

| Prevail Phenyl | 3,5 | 110 | 350 | 7 | L11 | |

| Prevail Cyano (CN) | 3,5 | 110 | 350 | - | L10 | |

| Prevail Amino (NH2) | 3,5 | 110 | 350 | - | L8 | |

| Prevail Silica | 3,5 | 110 | 350 | - | L3 | |

| Prevail Organic Acid | 3,5 | 110 | 350 | - | - | |

| Carbohydrate ES (polymer) | 5 | - | - | - | - |

Nano / Capillary LC Column ProteCol - SGE

| Packing Material | Particle Size (µm) | Pore Size (Å) | Surface Area (m2/g) | Carbon Load (%) | pH Range | USP Packing |

|---|---|---|---|---|---|---|

| ProteCol C18 | 3 | 120/300 | 350 | 17 | 2.0-7.5 | L1 |

| ProteCol C8 | 3 | 120/300 | 350 | 10 | 2.0-7.5 | L7 |

| ProteCol C4 | 3 | 120/300 | 350 | 2.0-7.5 | L26 | |

| ProteCol SCX | 3 | 120/300 | 350 | 2.0-7.5 | L9 |

Overview of MSPE sorbents

Sorbents for the MSPE technique are chosen to cover the widest possible field of applications. MSPE SpeExtra C18 is a hydrophobic type of octadecyl silica gel with a special endcapping. It is suitable for a wide range of analytes, showing lower retention for polar compounds. MSPE SpeExtra C18-P is a polar modified monomeric octadecyl silica gel. It offers different types of interactions: dipole-dipole, π-π and hydrophobic. It is therefore suitable for aromatic and polar compounds. MSPE SpeExtra HLB polymer sorbent with high specific surface area and special endcapping. It has a hydrophilic and lipophilic modification ensuring universal use and a higher capacity than C18 silica gel.

| MSPE sorbent | Particle size [µm] | Specific surface area [m 2 /g] | ||

| C18 | 60 | 310 | ||

| C18-P | 60 | 310 | ||

| HLB | 30 | 850 |

SPE Phases

This site encloses SPE phases overview includint their technical parameters. Further information about the products are available in the product catalogue.

Clean up SPE columns

Reverse phase hydrophobic

| Phase | Pore volume (cm3/g) | Pore Size (A) | Surface Area (m2/g) | Carbon Load (%) | End Capping | Feature |

|---|---|---|---|---|---|---|

| C2 Ethyl | 0.77 | 60 | 500 | 6.6 | YES/NO | |

| C4 n-Butyl | 0.77 | 60 | 500 | 8.5 | YES | |

| C8 Octyl | 0.77 | 60 | 500 | 11.1 | YES/NO | |

| C18 Octadecyl | 0.77 | 60 | 500 | 21.7 | YES/NO | |

| C30 Tricontyl | 0.77 | 60 | 500 | 20.0 | YES | |

| Cyclohexyl | 0.77 | 60 | 500 | 11.6 | YES/NO | |

| Phenyl | 0.77 | 60 | 500 | 11.0 | YES/NO |

Normal phase hydrophilic

| Phase | Pore volume (cm3/g) | Pore Size (A) | Surface Area (m2/g) | Carbon Load (%) | Feature | |

|---|---|---|---|---|---|---|

| Silica | 0.77 | 60 | 500 | N/A | ||

| Diol | 0.99 | 60 | 500 | 8.0 | ||

| Cyanopropyl | 0.77 | 60 | 500 | 9.0 | ||

| Florisil | 0.82 | 60 | 500 | N/A | ||

| Alumina, Acidic | 60 | 500 | N/A | |||

| Alumina, Basic | 60 | 500 | N/A | |||

| Alumina, Neutral | 60 | 500 | N/A | |||

| Carbon | N/A | 120/140 mesh |

Ion Exchange - Anion Exchange

| Phase | Pore volume (cm3/g) | pKa | Pore Size (A) | Surface Area (m2/g) | Carbon Load (%) | Exchange (meq/g) |

|---|---|---|---|---|---|---|

| Aminopropyl (1 amine) | 0.77 | 9.8 | 60 | 500 | 6.65 | 0.31 |

| N-2 Aminoethyl (1/2 amine) | 0.77 | 10.1; 10.9 | 60 | 500 | 11.1 | 0.32 |

| Diethylamino (3 amine) | 0.77 | 10.6 | 60 | 500 | 10.6 | 0.28 |

| Quarternary Amine Chloride | 0.77 | Always charged | 60 | 500 | 8.4 | 0.25 |

| Quarternary Amine Hydroxide | 0.77 | Always charged | 60 | 500 | 8.4 | 0.25 |

| Quarternary Amine Acetate | 0.77 | Always charged | 60 | 500 | 8.4 | 0.25 |

| Quarternary Amine Formate | 0.77 | Always charged | 60 | 500 | 8.4 | 0.25 |

| Polyimine | 0.77 | Always charged | 13.5 | 0.25 |

Ion Exchange - Cation Exchange

| Phase | Pore volume (cm3/g) | pKa | Pore Size (A) | Surface Area (m2/g) | Carbon Load (%) | Exchange (meq/g) |

|---|---|---|---|---|---|---|

| Carboxylic Acid | 0.77 | 4.8 | 60 | 500 | 9.2 | 0.17 |

| Propylsulfonic Acid | 0.77 | 1 | 60 | 500 | 7.1 | 0.18 |

| Benzenesulfonic Acid | 0.77 | Always charged | 60 | 500 | 11.0 | 0.32 |

| Benzenesulfonic Acid, High Load | 0.77 | Always charged | 60 | 500 | 15.0 | 0.65 |

| Triacetic Acid | 0.77 | 60 | 500 | 7.61 | Anion 0.17/Cation 0.06 |

Copolymeric phases

| Phase | Pore volume (cm3/g) | pKa | Pore Size (A) | Surface Area (m2/g) | Carbon Load (%) | Exchange (meq/g) |

|---|---|---|---|---|---|---|

| Aminopropyl + C8 | 0.77 | 9,8 | 60 | 500 | 12,3 | 0,163 |

| Quarternary Amine + C8 | 0.77 | Always charged | 60 | 500 | 13,6 | 0,160 |

| Carboxylic Acid + C8 | 0.77 | 4,8 | 60 | 500 | 2,5 | 0,105 |

| Propylsulfonic Acid + C8 | 0.77 | 1 | 60 | 500 | 14,62 | 0,114 |

| Benzenesulfonic Acid + C8 | 0,77 | Always charged | 60 | 500 | 12.3 | 0,072 |

| Cyanopropyl + C8 | 0,77 | N/A | 60 | 500 | 14,6 | 0,163 |

| Cyclohexyl + C8 | 0.77 | N/A | 60 | 500 | N/A | N/A |

GC Phases

On this page we provide an overview of the supplied stationary phases for gas chromatography (GC). Each is given details of its properties and the applications that are suitable for them. In the product catalog you can then choose a suitable quartz or metal capillary column for GC.

Stationary phases LION

Fused silica capillary columns

| Stationary phase | Temperature range | Composition | USP Phase |

|---|---|---|---|

| LN-1 | -60 to 370°C | 100% dimethyl polysiloxane | G2 |

| LN-1 MS | -60 to 370°C | 100% dimethyl polysiloxane | G2 |

| LN-1 HT | -60 to 430°C | 100% dimethyl polysiloxane | - |

| LN-5 | -60 to 370°C | 5% diphenyl/95% dimethyl polysiloxane | G27 |

| LN-5 Sil MS | -60 to 370°C | 5% diphenyl/95% dimethyl polysiloxane | G27 |

| LN-5 MS | -60 to 350°C | 5% phenyl - arylene - 95% dimethyl polysiloxane | G27 |

| LN-5 HT | -60 to 430°C | 5% diphenyl/95% dimethyl polysiloxane | - |

| LN-35 | 50 to 360°C | 35% diphenyl/65% dimethyl polysiloxane | G42 |

| LN-35 HT | -60 to 400°C | 35% diphenyl/65% dimethyl polysiloxane | G42 |

| LN-17 | 40 to 340°C | 50% diphenyl/50% dimethyl polysiloxane | G3 |

| LN-624 | -20 to 260°C | 6% cyanopropylphenyl/94% dimethyl polysiloxane | G43 |

| LN-FFAP | 40 to 260°C | Nitroterephthalic Acid Modified Polyethylene Glycol | G35 |

| LN-1701 | -20 to 300°C | 14% cyanopropylphenyl/86% dimethyl polysiloxane | G46 |

| LN-XLB | 30 to 360°C | Low polarity phases | - |

| LN-XLB-HT | 30 až 400°C | Low polarity phases | |

| LN-WAX | 40 to 260°C | Polyethylene Glycol | G16 |

| LN-WAX Plus | 20 to 260°C | Polyethylene Glycol | G16 |

UHPLC Phases

Raptor - RESTEK

| Packing Material | Particle Size (µm) | Pore Size (Å) | Effective Surface Area (m2/g) | Carbon Load (%) | pH Range |

|---|---|---|---|---|---|

| Raptor ARC-C18 | 1.8 | 90 | 125 | proprietary | 1.0-8.0 |

| Raptor ARC-C18 | 2.7 | 90 | 130 | proprietary | 1.0-8.0 |

| Raptor ARC-C18 | 5.0 | 90 | 100 | proprietary | 1.0-8.0 |

| Raptor C18 | 1.8 | 90 | 125 | proprietary | 2.0-8.0 |

| Raptor C18 | 2.7 | 90 | 130 | proprietary | 2.0-8.0 |

| Raptor C18 | 5.0 | 90 | 100 | proprietary | 2.0-8.0 |

| Raptor Biphenyl | 1.8 | 90 | 125 | proprietary | 1.5-8.0 |

| Raptor Biphenyl | 2.7 | 90 | 130 | proprietary | 1.5-8.0 |

| Raptor Biphenyl | 5.0 | 90 | 100 | proprietary | 1.5-8.0 |

| Raptor Fluorophenyl | 1.8 | 90 | 125 | proprietary | 2.0-8.0 |

| Raptor Fluorophenyl | 2.7 | 90 | 130 | proprietary | 2.0-8.0 |

| Raptor Fluorophenyl | 5.0 | 90 | 100 | proprietary | 2.0-8.0 |

| Raptor HILIC-Si | 2.7 | 90 | 150 | n/a | 2.0-8.0 |

| Raptor EtG/EtS | 2.7 | 90 | 130 | proprietary | 2.0-8.0 |

Raptor maximum pressure: 1,034 bar (1.8 μm), 600 bar (2.7 μm); 400 bar (5 μm). For maximum lifetime recommended maximum pressure for 1.8 µm particles is 830 bar.

PINNACLE DB - RESTEK

| Packing Material | Particle Size (µm) | Pore Size (Å) | Surface Area (m2/g) | Carbon Load (%) | pH Range |

|---|---|---|---|---|---|

| Pinnacle DB C18 | 1.9 | 140 | 150 | 11 | 2.5-8.0 |

| Pinnacle DB Aqueous C18 | 1.9 | 140 | 150 | 6 | 2.5-8.0 |

| Pinnacle DB C8 | 1.9 | 140 | 150 | 6 | 2.5-8.0 |

| Pinnacle DB CN | 1.9 | 140 | 150 | 4 | 2.5-8.0 |

| Pinnacle DB PFP | 1.9 | 140 | 150 | 6 | 2.5-8.0 |

| Pinnacle DB Biphenyl | 1.9 | 140 | 150 | 8 | 2.5-8.0 |

| Pinnacle DB IBD | 1.9 | 140 | 150 | proprietary | 2.5-8.0 |

| Pinnacle DB Silica | 1.9 | 140 | 150 | n/a | 2.5-8.0 |

dSPE (QuEChERS)

Resprep™ QuEChERS Products

QuEChERS Tubes For Extraction and Clean-Up of Pesticide Residues From Food Products

- Fast, simple sample extraction and cleanup using dSPE.

- Fourfold increases in sample throughput.

- Fourfold decreases in material cost.

- Convenient, ready to use centrifuge tubes with ultra pure, preweighed adsorbent mixes.

Quick, Easy, Cheap, Effective, Rugged, and Safe, the QuEChERS ("catchers") method is based on work done and published by the US Department of Agriculture Eastern Regional Research Center in Wyndmoor, PA.(1) Researchers there were looking for a simple, effective, and inexpensive way to extract and clean pesticide residues from the many varied sample matrices with which they routinely worked. They had been using the Modified Luke Extraction Method, which is highly effective and rugged, but is both labor and glassware intensive, leading to a relatively high cost per sample. Solid phase extraction also had been effective, but the complex matrices the investigators were dealing with required multiple individual cartridges and packings to remove the many classes of interferences, adding costs and complexity to the process. A new method would have to remove sugars, lipids, organic acids, sterols, proteins, pigments and excess water, any of which often are present, but still be easy to use and inexpensive.

Quick, Easy, Cheap, Effective, Rugged, and Safe, the QuEChERS ("catchers") method is based on work done and published by the US Department of Agriculture Eastern Regional Research Center in Wyndmoor, PA.(1) Researchers there were looking for a simple, effective, and inexpensive way to extract and clean pesticide residues from the many varied sample matrices with which they routinely worked. They had been using the Modified Luke Extraction Method, which is highly effective and rugged, but is both labor and glassware intensive, leading to a relatively high cost per sample. Solid phase extraction also had been effective, but the complex matrices the investigators were dealing with required multiple individual cartridges and packings to remove the many classes of interferences, adding costs and complexity to the process. A new method would have to remove sugars, lipids, organic acids, sterols, proteins, pigments and excess water, any of which often are present, but still be easy to use and inexpensive.

The researchers developed a simple two-step procedure. First, the homogenized samples are extracted and partitioned, using an organic solvent and salt solution. Then, the supernatant is further extracted and cleaned, using a dispersive SPE technique. Multiple adsorbents are placed in a centrifuge tube, along with the 1mL of organic solvent and the extracted residues partitioned from step 1. The contents are thoroughly mixed, then centrifuged, producing a clean extract ready for a variety of GC or HPLC analytical techniques.(2) Validation and proficiency data for the QuEChERS method are available for a wide variety of pesticides in several common food matrices at www.quechers.com.

Using the dispersive SPE approach, the quantity and type of adsorbents, as well as the pH and polarity of the solvent, can be easily adjusted for differing matrix interferences and "difficult" analytes. Results from this approach have been verified and modified at several USDA and Food and Drug Administration labs, and the method now is widely accepted for many types of pesticide residue samples.

Restek products make this approach even simpler. The centrifuge tube format, available in 2mL and 15mL sizes, contains magnesium sulfate (to partition water from organic solvent) and PSA* adsorbent (to remove sugars and fatty acids), with or without graphitized carbon (to remove pigments and sterols) or C18 packing (to remove nonpolar interferences). Custom products are available by quote request. If you are frustrated by the time and cost involved with your current approach to pesticide sample cleanup, we suggest you try this simple and economical new method.

We have products compliant with AOAC, Multi-miniresidue and Draft European methods.

Inforamtion about products is available here.

References:

- Anastassiades, M., S.J. Lehotay, D. Stajnbaher, F.J. Schenck, Fast and Easy Multiresidue Method Employing Acetonitrile Extraction/Partitioning and "Dispersive Solid-Phase Extraction" for the Determination of Pesticide Residues in Produce, J AOAC International, 2003, vol 86 no 22, pp 412-431.

- Schenck, F.J., SPE Cleanup and the Analysis of PPB Levels of Pesticides in Fruits and Vegetables. Florida Pesticide Residue Workshop, 2002

MEPS Phases

SGE

| Phase | Particle size (µm) | Pore Size (A) |

|---|---|---|

| Silica | 45 | 60 |

| C2 | 45 | 60 |

| C8 | 45 | 60 |

| C8+SCX* | 45 | 60 |

| C18 | 45 | 60 |

*C8+SCX BINS are labelled as M1.

The BINs can be used up to 40 - 100 extractions. General preparation time is 1 - 2 minutes.

Stationary phases

Chromatography, either GC, HPLC, SPE, FLASH or preparative, uses many types of stationary phases. Here you wil find detailed information about stationary phases.

Chromatography, either GC, HPLC, SPE, FLASH or preparative, uses many types of stationary phases. Here you wil find detailed information about stationary phases.

Stationary phases for analytical separation

Stationary phases for sample preparation

- SPE

- dSPE (QuEChERS)

- IAC (Immunoaffinity Columns)

- MEPS (Micro Extraction by Packed Sorbent)

- FLASH

- BULK (media for preparative chromatography)

Leak Free SilTite metal ferrules for GC & GC/MS

SilTite ferrules are a unique metal ferrule specifically designed for connecting fused silica GC columns and tubing to mass spectrometer interfaces and injectors. Once fitted, SilTite ferrules provide a continuous leak free connection without the need to re-tighten the nut after a few temperature cycles. SilTite ferrules make Graphite/Vespel® ferrules obsolete for use in GC-MS connections. Their performance and cost effectiveness also makes them ideal for connecting GC columns to injectors and atmospheric detectors.

SilTite ferrules are a unique metal ferrule specifically designed for connecting fused silica GC columns and tubing to mass spectrometer interfaces and injectors. Once fitted, SilTite ferrules provide a continuous leak free connection without the need to re-tighten the nut after a few temperature cycles. SilTite ferrules make Graphite/Vespel® ferrules obsolete for use in GC-MS connections. Their performance and cost effectiveness also makes them ideal for connecting GC columns to injectors and atmospheric detectors.

Why choose SilTite ferrules?

- Eliminates leaks (See figures below)

- Never needs re-tightening, even after temperature cycling

- Ferrule remains permanently fixed to the column but does not adhere to the SilTite nut

- No contamination from Vespel or graphite materials - 100% metal

- Ideal for high pressure applications

- Also available for injector interfaces

- >500°C maximum temperature

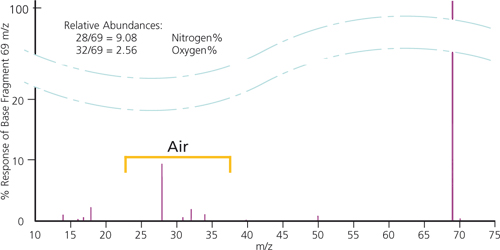

Figure 1. MS trace using a graphite Vespel ferrule after 5 temperature cycles.

Figure 2. MS trace using a SilTite ferrule after 5 temperature cycles. (Using an MS, no leaks can be detected, even after 400 temperature cycles between 70ºC and 400ºC).

Agilent S/SL inlet seal improvment

Washerless, Leak-Tight Seal for Agilent GCs ensures better tightness and easier handling than original part.

Washerless, Leak-Tight Seal for Agilent GCs ensures better tightness and easier handling than original part.

- Prevents oxygen from permeating the carrier gas, increasing column lifetime.

- Vespel® ring in top surface reduces operator variability by requiring minimal torque to seal.

- Vespel® ring in bottom surface simplifies installation—eliminates the washer.

In Agilent split/splitless injection ports, it can be difficult to make and maintain a good seal with a conventional metal inlet disk. The metal-to-metal seal dictates that you apply considerable torque to the reducing nut, and, based on our testing, this does not ensure a leak-tight seal. Over the course of oven temperature cycling, metal seals are prone to leaks, which ultimately can degrade the capillary column and cause other analytical difficulties.

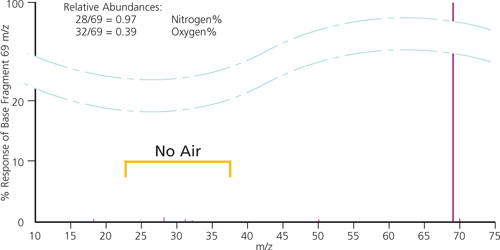

Agilent and Restek seal tightness comparison

Patented Dual Vespel® Ring Inlet Seal (Restek) greatly improves injection port performance—it stays sealed, even after repeated temperature cycles, without retightening the reducing nut| This seal features two soft Vespel® rings, one embedded in its top surface and the other embedded in its bottom surface. These rings eliminate the need for a washer, and ensure very little torque is needed to make a leak-tight seal. The rings will not harm the critical seal in the injector body, or any other surface, and are outside the sample flow path. Tests using a high sensitivity helium leak detector show Dual Vespel® Ring Inlet Seals will seal equally effectively at torques from 5 in. lb. to 60 in. lb.

Why trust a metal-to-metal seal when you can make leak-tight seals quickly and easily—and more reliably—without a washer, with a Restek Dual Vespel® Ring Inlet Seal. Use a stainless steel seal for analyses of unreactive compounds. To reduce breakdown and adsorption of active compounds, use a gold-plated or Siltek®-treated seal. The gold surface offers better inertness than untreated stainless steel. Siltek® treatment provides inertness similar to that of a fused silica capillary column.

Seal options

- Stainless Steel

- Gold plated

- Siltek deactivated

0

0

0

0