Chromatography

Setting linear velocity

The linear velocity is an important parameter in chromatography. It has an influence on chromatography resolution and therefore setting the dead volume is basic part of method development.

Linear velocity measurement in GC

To set a dead time, inject 2 µl of a non-retained gaseous substance, which is compatible with the detector. Take a gas-tight syringe and draw the headspace over neat compound. Accurately mark the injection starting time and peak elution time.

| Detector | Compound |

|---|---|

| FID | methane, propane, butane |

| ECD | methylen chloride, air (at lower oven temperatures) |

| TCD | methane, butane, air (at lower oven temperatures) |

| NPD | acetonitrile, air (at lower oven temperatures) |

| MS | propane, butane, argon, air (at lower oven temperatures) |

| PID | acetylene, ethylene |

Note: Some compounds may be slightly retained on thick-film phase, however, they will be reproducible for similar column types.

Handling chiral columns

Cellulose/Amylose chiral column use and care

Shipping Solvent

n-Hexane/2-propanol (9:1, v/v)

Test Certificate

Each column is individually tested before shipment. A test certificate showing the separation parameters for trans-stilbene oxide is enclosed with each column.

Mobile Phase Compatibility

Chiral columns can be used with normal phase (alkane/alcohol), reversed phase (aqueous methanol, aqueous acetonitrile or appropriate buffer/methanol or buffer/acetonitrile mixtures), as well as with pure polar organicsolvents (low molecular weight alcohols, acetonitrile or their mixtures).

Solvent Switching

An appropriate column washing procedure must be applied when changing from one mobile phase to another. The miscibility of the different mobile phase components must be carefully considered for this wash. To safely transfer a column from hexane to methanol (or acetonitrile) or from methanol (or acetonitrile) to hexane, use 100 % 2-propanol as transition solvent at a flow rate of 0.2-0.5 mL/min. Ten column volumes of 2-propanol (i.e. 25 mL for a 250 x 4.6 mm i.d. column or 15 mL for a 150 x 4.6 mm i.d. column) are sufficient for completely removing the old mobile phase. To safely transfer a column from normal phase to reversed phase conditions flush the column with 100 % 2-propanol at 0.2-0.5 mL/min for minimum ten column volumes. In addition, when the buffer salt additive of the RP mobile phase is insoluble in 2-propanol, flush the column briefly with water before switching to a buffered mobile phase. We recommend the use of dedicated Lux columns to reversed phase operation hence avoiding the need of converting columns used in normal phase elution mode to reversed phase or vice versa.

Use of Mobile Phase Modifiers

For basic samples or acidic chiral compounds, it may be necessary to use an appropriate mobile phase modifier in order to achieve chiral resolution and to insure proper peak shapes. Diethylamine, ethanolamine and butyl amine in the concentration range 0.1-0.5 % can be used with basic analytes, while trifluoroacetic or acetic acid (0.1-0.5 %; typically 0.1-0.2 %) with acidic analytes. Mixtures of basic and acidic mobile phase additives are acceptable (e.g. diethyl amine acetate or trifluoroacetate). Lux columns will deliver consistent results when operated with mobile phases containing additives at the concentration levels specified above. However, limited decrease in column efficiency may occur when a column is used in combination with these additives. Therefore, we advise to dedicate columns to mobile phases containing basic additives. Mobile Phase Restrictions Lux chiral stationary phases are prepared by coating silica with various polysaccharide derivatives. Therefore, any solvent dissolving the polysaccharide derivative (such as tetrahydrofurane, acetone, chlorinated hydrocarbons, ethylacetate, dimethylsulfoxide, dimethylformamide, N-methylformamide, etc.) must be avoided even in trace amounts (e.g. even as sample solvent).

Operating Backpressure

The mobile phase flow rate should be set such that the column backpressure stays below 300 bar (4300 psi). This maximum backpressure should not be exceeded for long periods of time.

Operating Temperatures

With standard mobile phases (such as alkane/alcohol) the column can be used in the temperature range 0-50 °C.

Column Storage

Column storage for a longer period of time is recommended in n-hexane/2-propanol (9:1, v/v). Columns used in reversed phase conditions should be first flushed with water (whenever a buffer salt was used as RP mobile phase additive) and then with methanol (or with methanol only when no salt was used). The column can be stored in methanol.

Extending Lifetime and Reconditioning

We recommend the use of guard cartridges to extend the lifetime of your column, especially with samples extracted from complex matrixes. Ideally, samples must be completely dissolved in the mobile phase or filtered through a syringe filter of approximately 0.45 μm porosity.

Hints and tips

This site includes technical information, hints and tips for your decisions, and recommendation for selecting right chromatography accessories.

This site includes technical information, hints and tips for your decisions, and recommendation for selecting right chromatography accessories.

- Agilent GC inlet seal improvment

- Dynamic headspace

- GC column conditioning procedure

- GC column installation

- GC liners

- GC septa selection

- Glassware deactivation procedure

- How to improve GC capillary column connections

- How to increase signal/noise ratio in GC systems

- How to set optimum linear velocity

- How to handle chiral HPLC columns

- LC separation performance improvement

- LC column selection

- Syringe care

- Syringe tip selection

- Thermal desorption

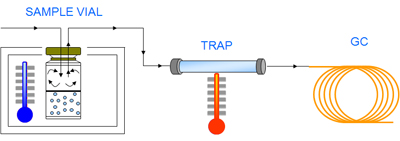

Dynamic Headspace

Dynamic Headspace (DHS) can be used for a wide range of environmental applications. Pollutants can be detected in drinking water, river water, and waste water. These matrixes include chemicals of different polarity, volatility, such as chlorinated hudrocarbons, aromatics, oxygenates, etc. Dynamic Headspace also can be used for further applications:

- characterization of spices, herbs, foods, soaps

- residual monomer and other VOC in polymers

- residual solvents in food packaging

- "green label" product testing

- OVIs in pharmaceutical products

- trace impurities in active pharmaceuticals ingredients

- metabolites in biological fluids (aromatic hydrocarbons in urine, benzene in blood)

Capillary GC column installation

Brief procedure for column installation

Brief procedure for column installation

- Cool all heated zones of GC

- Check gas purifiers and if they are spent, replace them.

- Clean injector and detector

- Replace injector/detector liners with new ones.

- Replace critical injector and detector seals.

- Replace septum in the injector.

- Set make-up and detector gas flow rates.

- Carefully inspect the column for damage or breakage.

- Install a nut and ferrule on each end of the column.

- Cut 10 centimeters from each end of the column. Use a sapphire scribe or ceramic scoring wafer to cut fused silica capillary columns. Use the serrated edge of a ceramic scoring wafer or the edge of a sharp file to cut metal capillary columns. See our catalogue for capillary cuting tools.

- Mount the capillary column in the oven using a bracket that protects the column from becoming scratched or abraded.

- Insert column the appropriate distance into the inlet as indicated in the instrument manual.

- Install the column so that the capillary does not touch the oven walls.

- Set the approximate column flow rate by adjusting the head pressure to the value listed on the test chromatogram included with the column.

- Set split vent, septa purge, and any other applicable inlet gases according to the instrument specifications.

- Confirm the flow by immersing the column outlet in a vial of solvent (acetone or isopropyl alcohol).

- Insert column the appropriate distance into the detector as indicated in the instrument manual.

- Check for inlet and outlet leaks using a thermal conductivity leak detector. Do not use soaps or liquid-based leak detectors or the column may be damaged.

- Set injector and detector temperatures. Turn the detector on when the temperatures have equilibrated. Caution - do not exceed the phase's maximum operating temperature!

- To set the proper dead time (linear velocity), inject methane or a non-retained substance compatible with the detector being used.

- Verify system integrity by checking the dead volume peak. It should not tail.

- Condition the column at its maximum operating temperature to stabilize the baseline. (See the test chromatogram included with the column for the maximum temperature.)

- Set oven to appropriate temperature and inject methane or an appropriate unretained substance, again to set the proper linear velocity.

- Inject a duplicate of the original test mixture or your specific test mixture to confirm proper installation, system, and column performance.

- Calibrate the instrument and inject samples.

Note: If the column is new, you have to run conditioning procedure prior setting the proper dead time.

Unit Conversions

HPLC capillaries volume chart

| ID (mm) | ID (inch) | µl/cm | µl/inch | ID (mm) | ID (inch) | µl/cm | µl/inch | |

|---|---|---|---|---|---|---|---|---|

| 0.050 | 0.002" | 0.02 | 0.05 | 1.00 | 0.040" | 7.85 | 20.59 | |

| 0.064 | 0.0025" | 0.03 | 0.08 | 1.40 | 0.055" | 15.39 | 38.93 | |

| 0.075 | 0.003" | 0.04 | 0.12 | 1.52 | 0.060" | 18.15 | 46.33 | |

| 0.10 | 0.004" | 0.08 | 0.21 | 1.59 | 0.062" | 19.86 | 49.47 | |

| 0.13 | 0.005" | 0.13 | 0.32 | 1.65 | 0.065" | 21.38 | 54.38 | |

| 0.17 | 0.0067" | 0.23 | 0.58 | 1.70 | 0.067" | 22.70 | 57.78 | |

| 0.18 | 0.007" | 0.25 | 0.63 | 1.78 | 0.070" | 24.88 | 63.06 | |

| 0.25 | 0.010" | 0.49 | 1.29 | 2.00 | 0.079" | 31.42 | 80.32 | |

| 0.38 | 0.015" | 1.13 | 2.90 | 2.10 | 0.083" | 34.64 | 88.66 | |

| 0.50 | 0.020" | 1.96 | 5.15 | 2.16 | 0.085" | 36.64 | 92.99 | |

| 0.75 | 0.030" | 4.42 | 11.58 | 2.40 | 0.094" | 45.24 | 113.72 |

UV cutoff of mobile phase aditives

| Aditivum | UV Cutoff (nm) |

| Acetic acid, 1 % | 230 |

| Ammonium acetate, 10 mM | 205 |

| Ammonium carbonate, 10 mM | 190 |

| Ammonium Hydrogenphosphate, 50 mM | 205 |

| CAPS 3-(cyklohexylamino)ethan sulfonic acid, 0,1 % | 215 |

| EDTA, 1 mM | 190 |

| Hydrochloric acid, 0,1 % | 190 |

| Kalium Hydrogenphosphate, 10 mM | 190 |

| Kalium Dihydrogenphosphate, 10 mM | 190 |

| MES 2-(N-morfolino)ethan sulfonic acid, pH 6,0, 10 mM | 215 |

| Natrium acetate, 10 mM | 205 |

| Natrium citrate, 10 mM | 225 |

| Natrium dodecylsulfate, 10 mM | 190 |

| Natrium formate, 10 mM | 200 |

| Natrium hexansulfonic acid, 5 mM | 225 |

| TEA, (triethylamine), 1% | 235 |

| TFA, (trifluoroacetic acid), 0,1 % | 190 |

| Tetrabutylammonium dihydrogen phosphate, 5 mM | 200 |

| TRIS HCl (Tris(hydroxylmethyl)aminomethan), pH 7,0, 20 mM | 202 |

| TRIS HCl (Tris(hydroxylmethyl)aminomethan), pH 8,0, 20 mM | 212 |

Unit conversions and tables

Unit conversions:

Unit conversions:

- Useful tables in chromatography

- Acid and bases pK used as an additivum for mobilne phases in HPLC

- UV cutoff of mobile phase components

- Column selection based on injection voluem and column capactiy

- Capillary choise for different flow rates

- ChromShell calculator (WE PREPARE)

- Pressure prediction in dependance of particle size, column length and diameter

- Viskosity of solvent mixtures

- Properties of HPLC solvents

- Particle size conversion

Dosing pumps

Dosing pumps

Dosing pumps are used in many applications, in laboratories and within industry. Often we see the needs, when we require dose liquids under specific conditions:

- High pressure dosing (reaction chambers, aparatures)

- High temperatures dosing

- Injection of reactive substances

- Dosing of viscous media

For all above mentioned applications it is possible to use technology that has been proven in the area of high performance liquid chromatography (HPLC). These are double-piston pumps AZURA (Knauer), which use sphire pistons enabling precise continuous dosing under high pressure. These pumps can work with flow of 0,01 to 1000 ml/min, under temperatures of -10°C to +120°C and with viscous media up to 1000 mPa.s.

For all above mentioned applications it is possible to use technology that has been proven in the area of high performance liquid chromatography (HPLC). These are double-piston pumps AZURA (Knauer), which use sphire pistons enabling precise continuous dosing under high pressure. These pumps can work with flow of 0,01 to 1000 ml/min, under temperatures of -10°C to +120°C and with viscous media up to 1000 mPa.s.

The pumps can be especially equipped so they can be used in specific application like hazardous areas.

Nice example of use of AZURA pumps is dosing of sulphur trioxide in production of methanesulfonic acid (MSA).

Materials

Pump head are available in following materials:

- Ceramic

- Hastelloy C-276

- Stainless steel

- Titanum

- Stainless steel/Titanum

Further information about models are available here.

TOPAZ Liners

True Blue Performance

True Blue Performance

Exceptionally inert, Topaz™ inlet liners, with a new state-of-the-art deactivation,improve trace level analysis.

- Increase accuracy and precision.

- Lower detection limits.

- Use wool with confidence.

When faced with complex choices, simple solutions stand out. TOPAZ™ inlet liners from Restek use a comprehensive, state-of-the-art deactivation and are the only blue liners on the market-making them an easy-to-recognize solution to common inlet problems.

The innovative deactivation used for TOPAZ™ liners results in exceptional inertness for a wide range of analyte chemistries. By reducing active sites and enhancing analyte transfer to the column, these liners increase accuracy and precision, allowing lower detection limits for many active compounds. In addition to improved data quality, you’ll benefit from fewer liner changes and less downtime for maintenance.

Selecting the right liner for your application can be a challenging task. TOPAZ™ inlet liners make the choice simple; the comprehensive deactivation, distinctive colour, and availability in popular configurations mean TOPAZ™ liners are the best choice for optimizing chromatographic performance. Regardless of your application, TOPAZ™ liners provide reliable inertness and assured performance, dayafter-day and analysis-after-analysis.

0

0

0

0